I didn’t really know what to expect when I first started working as a research technician in the Soil and Ecosystem Ecology lab at the University of Manchester. So, for anyone else unsure what a soil scientist does, here’s an example of what my week contains during my latest contract there (but bear in mind, I’m only a few rungs away from the bottom of the ladder, so more senior scientists workloads would differ quite drastically – probably with a lot more planning and paperwork from my experience).

Soil sieving – hours and hours (and hours) of soil sieving. We’re running greenhouse experiments at the moment, that will be repeated later in the project at field sites in Yorkshire. As these sites have already been chosen, Angie decided to use soil from them in the greenhouse stage, in an attempt to make the results more comparable. What this means for me though, is those 8 bags of soil need to be sieved to remove plants, creatures, seeds, stones etc, and to homogenise them (creating a sort of ‘average soil’). I often worked alone in the greenhouse, and with it being just a physical job I could stick my earphones in and zone out, listening to a whole series of “Just a Minute” on my phone.

Soil sieving – hours and hours (and hours) of soil sieving. We’re running greenhouse experiments at the moment, that will be repeated later in the project at field sites in Yorkshire. As these sites have already been chosen, Angie decided to use soil from them in the greenhouse stage, in an attempt to make the results more comparable. What this means for me though, is those 8 bags of soil need to be sieved to remove plants, creatures, seeds, stones etc, and to homogenise them (creating a sort of ‘average soil’). I often worked alone in the greenhouse, and with it being just a physical job I could stick my earphones in and zone out, listening to a whole series of “Just a Minute” on my phone.

Root cleaning – As will happen with the plants currently growing in our greenhouses, and to be grown in the field eventually, some previous samples have begun to be prepared for analysis. My task was to clean the harvested root clusters, and to pick out any stubborn pieces of non-living root material (that is to say, not living at the point at which they were harvested). This involved hours of intricate tweezer manipulation in combination with repeated rinsing and dunking. It sounds like a fairly tedious job on paper, but I found a strange kind of satisfaction in it, in getting all the bits out and ending up with a pleasingly clean sample.

TE@M – Technical Excellence @ Manchester – This was a launch event for a new initiative within the university, to make connections between the many technical staff that are often under-appreciated, and allow for collaborations and sharing of resources. There were presentations and talks, opportunities to vote on future events and report on our experiences of praise, a pretty tasty lunch and some time to network.

TE@M – Technical Excellence @ Manchester – This was a launch event for a new initiative within the university, to make connections between the many technical staff that are often under-appreciated, and allow for collaborations and sharing of resources. There were presentations and talks, opportunities to vote on future events and report on our experiences of praise, a pretty tasty lunch and some time to network.

Christmas do – OK, this is a bit of a cheat, since Christmas meals aren’t a regular thing. But I was pleased to be working there over Christmas, we had a lot of fun attending the School Christmas party (with free food and drink, a raffle, and even the current party ‘must have’ – a photo booth) and later that day, going for our lab group meal at a cute place called the Allotment.

From back left: Reuben, me, Jon, Ellen, Debbie, Chris, Amy, Jenny and Irene.

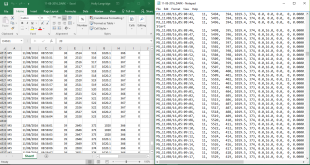

Data processing – The project has already generated a large amount of IRGA data (that is gas sampling data, monitoring the carbon flux in an enclosed space – in this case a light and dark container placed over the plants, making a tight seal with the plastic pipe segment set into the ground). I needed to remove the segments of data we wanted for each plot from the text file and make a new excel sheet for light and dark on each sampling date. A simple enough task but time consuming and requiring good concentration because there were little errors scattered throughout.

Data processing – The project has already generated a large amount of IRGA data (that is gas sampling data, monitoring the carbon flux in an enclosed space – in this case a light and dark container placed over the plants, making a tight seal with the plastic pipe segment set into the ground). I needed to remove the segments of data we wanted for each plot from the text file and make a new excel sheet for light and dark on each sampling date. A simple enough task but time consuming and requiring good concentration because there were little errors scattered throughout.

Cleaning the AutoAnalyzer – I finished my data processing ahead of schedule but my line manager was off due to illness, so I pimped myself out to my other colleagues, and ended up helping the lab manager clean the AutoAnalyzer. They’ve named it Colin and there’s a note saying ‘Colin’ firmly and permanently hung on the wall of shame, because it’s temperamental at the best of times. Debbie and I removed the covers to clean the chain and rollers, then swapped out the tubes for new ones (being careful to connect them up correctly and change any of the nipples that had started to corrode).

Cleaning the AutoAnalyzer – I finished my data processing ahead of schedule but my line manager was off due to illness, so I pimped myself out to my other colleagues, and ended up helping the lab manager clean the AutoAnalyzer. They’ve named it Colin and there’s a note saying ‘Colin’ firmly and permanently hung on the wall of shame, because it’s temperamental at the best of times. Debbie and I removed the covers to clean the chain and rollers, then swapped out the tubes for new ones (being careful to connect them up correctly and change any of the nipples that had started to corrode).

Transplanting seedlings – As well as sieving down at the greenhouses, I have also carried out a lot of aphid checks and planted out some seedlings from trays into their own pots. One of the species being transplanted was a bit mischievous; Rumex acetosa is a broad leaf that had grown tangled into each other, much like my hair after a night out! There were even a few stalks that had grown through holes in other leaves – making it quite time consuming to extricate individual plants without damaging them.

Weighing dry biomass – The biomass from earlier fieldwork has already been collected, weighed and dried by my predecessor. It was also already separated into species meaning when I came to weight it, some samples were a single blade of grass! This meant I had to use the more sensitive balance in the lab, but that presented a slight issue as it was taking a long time to settle and tare. I tried moving away from any equipment in the lab that caused vibrations, then moved away from the air vents in case a cross wind was catching the weigh boat. This helped but it was still slow progress with how long it would take to settle on a weight, so I then moved into the little windowless soil prep room which doesn’t have air conditioning, and voila! As annoying as it was to have those issues, I do enjoy having to use my brain to problem solve. This didn’t resolve the other annoyance however, of some plant material being statically attracted to the weigh boat, making it dance around when I tried to tweeze it back into the paper bag!